Solution

Solution

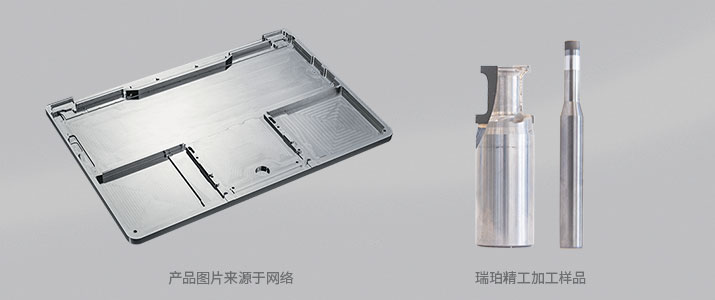

The five-axis laser tool processing machine offers high-precision hardware performance, meeting the demands of precision machining in electronics products.

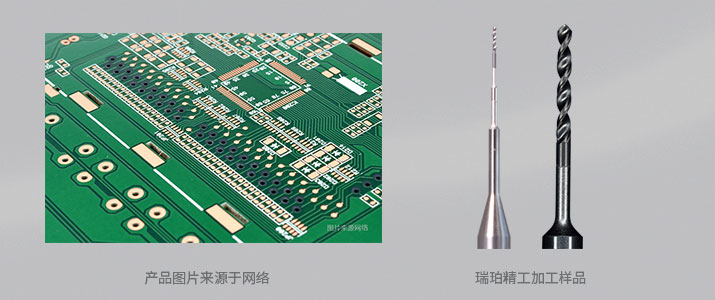

Tools produced by the five-axis laser tool processing machine can be used for processing internal cavities and contour profiles of electronics products such as laptops & smartphones, while micro-drills are suitable for PCB drilling operations.

The processed tool cutting edges exhibit excellent quality and high precision, contributing to improved manufacturing quality of electronic products;

The equipment utilizes ultra-short pulse laser sources and a granite bed design, ensuring machining accuracy and stability while enhancing product consistency;

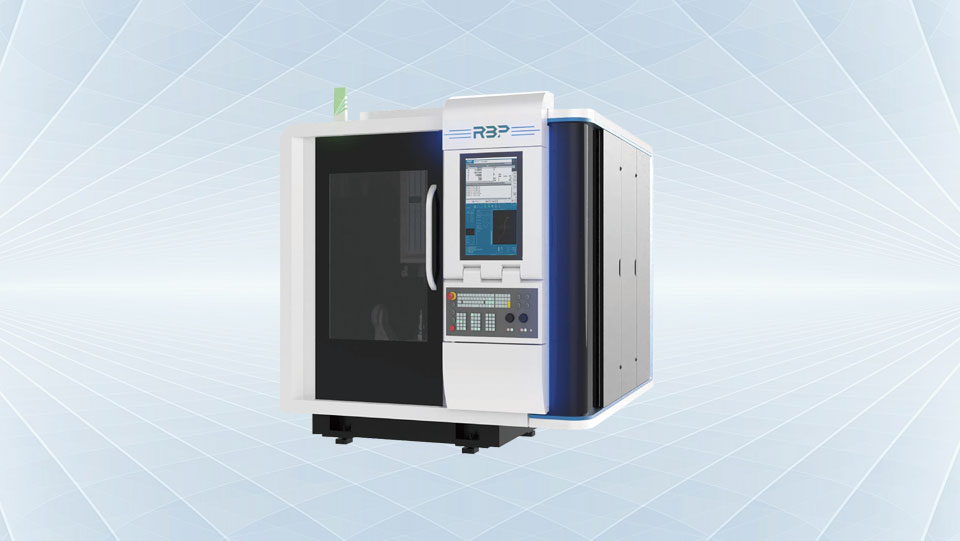

The LFS-U model offers distinct advantages for micro-tool processing in electronics, with non-contact laser machining capable of handling tools as small as 0.2mm in diameter;

The LFS-U employs ultra-short pulse laser technology, delivering high processing efficiency to meet mass production requirements;

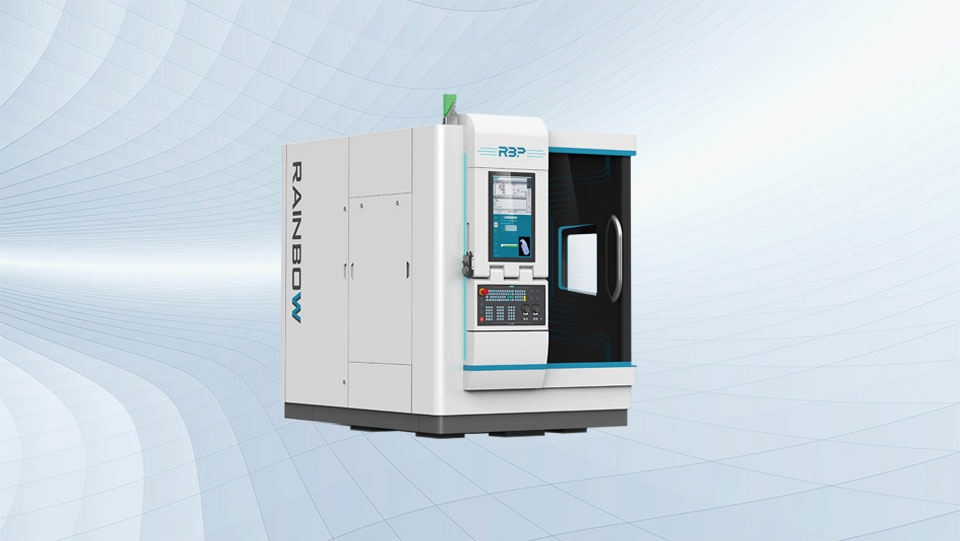

The LFS-M80 integrates turning, cutting, and engraving functions, providing greater convenience for customer product processing;

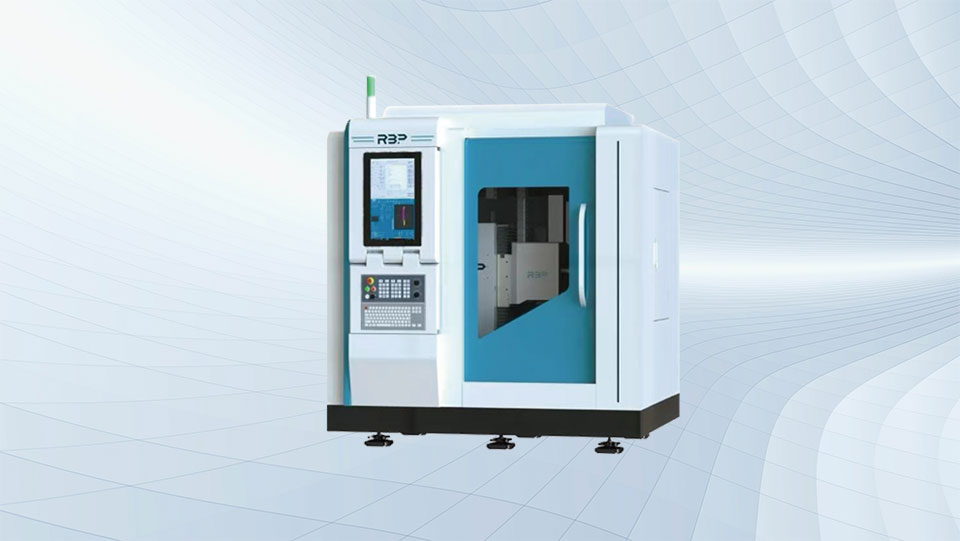

The LFS-P provides a machining range of 240mm x 350mm and supports combined roughing and finishing operations.