Solution

Solution

The five-axis laser tool processing machine features high precision and high stability, enabling the high-accuracy manufacturing of mold components. Through precise CNC programming and advanced cutting techniques, it meets the stringent requirements of mold production.

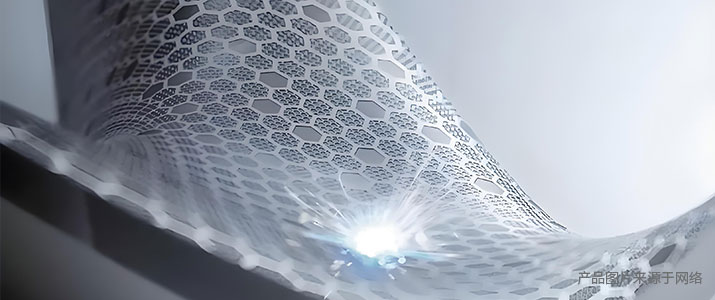

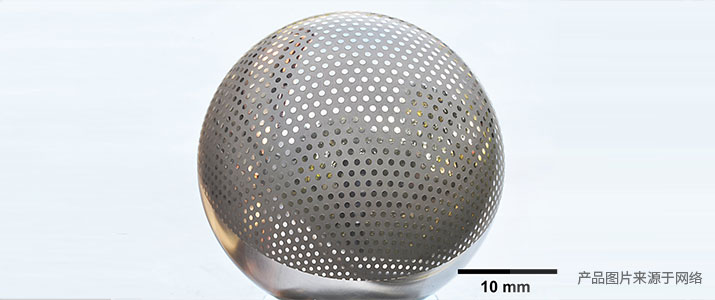

The equipment is primarily used for fine processing tasks such as surface texturing and 3D panel engraving with PCD micro-drills.

The LFS-U equipment utilizes ultra-short pulse laser sources with nanosecond & femtosecond dual lasers, delivering high processing efficiency;

The equipment adopts self-developed laser sources and algorithm software, enabling customized solution design for customers while effectively adapting to evolving market demands, resulting in higher efficiency and faster response for new product development;

It achieves higher motion precision and positioning accuracy, enabling precise processing of fine structures on mold surfaces.