Solution

Solution

Laser processing technology enables high-precision micro-tool machining, which is particularly critical for the complex materials and structures used in aircraft manufacturing.

The sharpness and wear resistance of PCD tools effectively address challenging issues such as material delamination and burrs during the processing of composite materials in the aerospace field.

Given the high manufacturing costs and stringent yield requirements in the aerospace industry, advanced tool processing techniques ensure stability in tool performance, thereby contributing to the advancement of national aerospace programs.

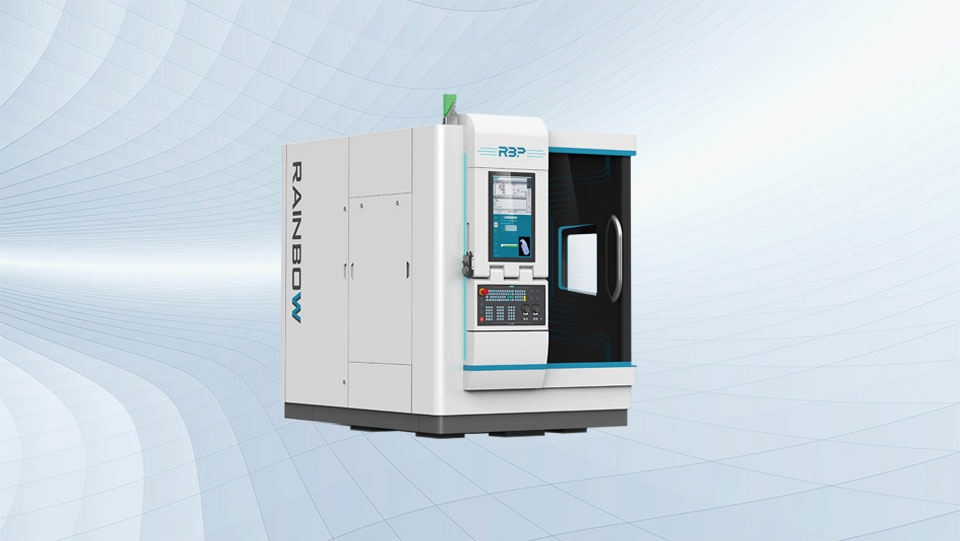

After years of relentless efforts in the field of tool manufacturing and a dedicated focus on advanced technology R&D, RAINBOW Precision can provide the aviation industry with exceptional integrated solutions for tool and special material processing;

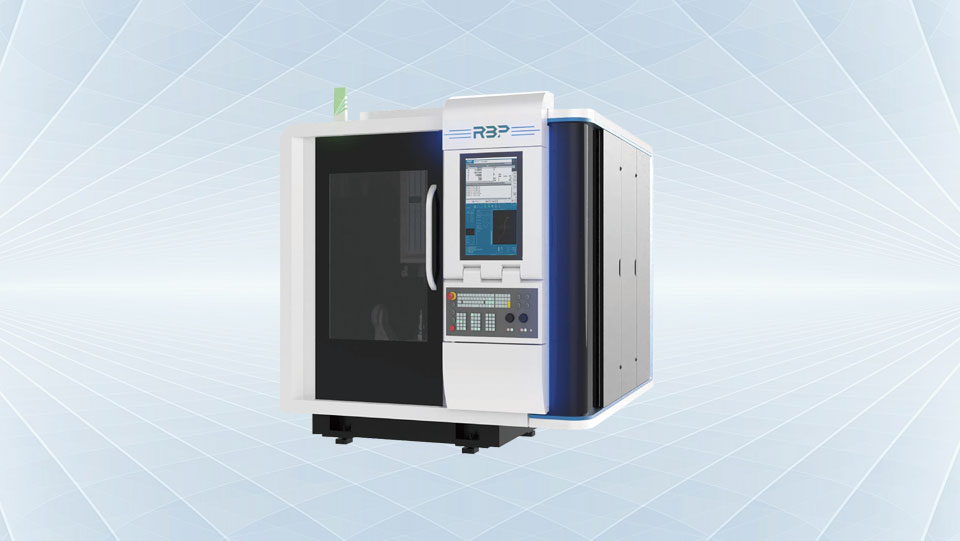

The LFS-U model offers maximum acceleration exceeding 1g, utilizes dual lasers, and integrates roughing and finishing processes, ensuring high efficiency and superior quality;

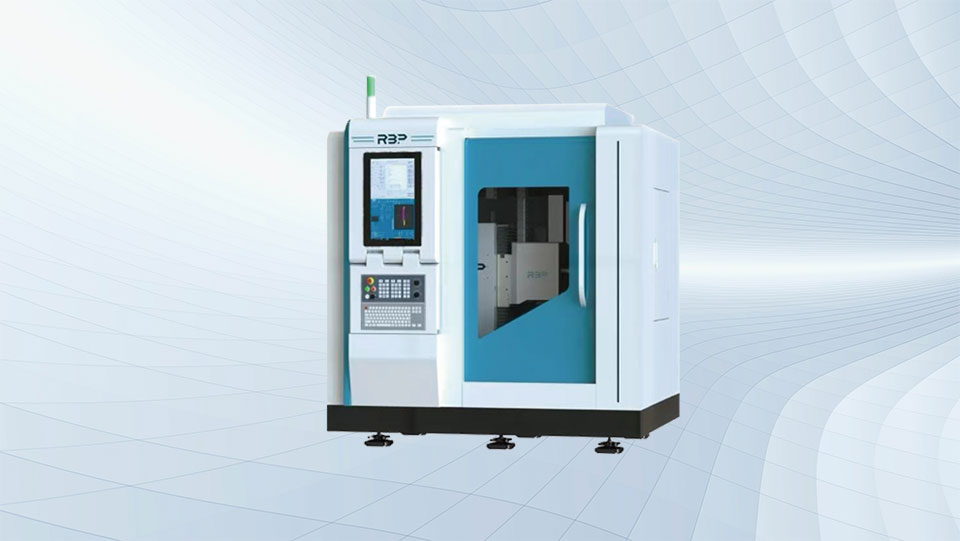

The LFS-M80 equipment combines turning, cutting, and engraving functions, providing greater convenience for customer product processing;

Enables rapid technological iteration and innovation to meet the evolving and updating demands of products and new materials in the aerospace industry.