Product Center

Product Center

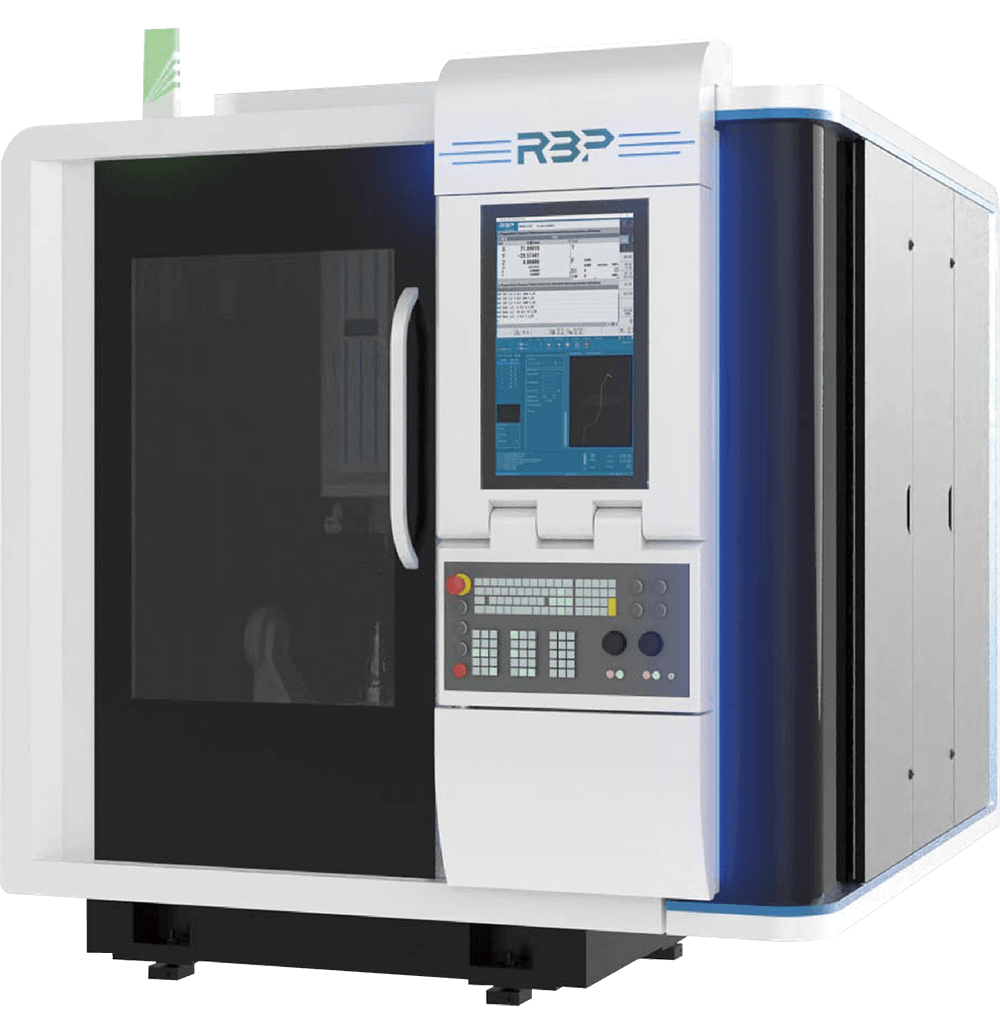

Five-Axis Laser Tool Processing Machine LFS-M80

Laser three-axis + dynamic five-axis spatial linkage technology

High-precision hardware performance + linear motor combination, ensuring high operational speed

Independently developed CAM software based on Siemens five-axis system, integrated with laser processing technology

Excellent cutting edge quality and high contour accuracy

High-strength bed structure, strong corrosion resistance, and thermal stability to ensure machining precision and stability

Details

Application industry:

Specializes in complex contour machining of 3C diamond-form tools, and is suitable for edge cutting, profile turning, and 3D shaping of ultra-hard materials and tools such as PCD, CVD, MCD, and PCBN.

Laser technology:

| Types | Parameters |

|---|---|

| Motion Control | X/Y/Z positioning accuracy: ±2 μm; A/C rotary-axis accuracy: ±2 arcsec. |

| CAM Software | Generates 5-axis spatial toolpaths from imported 2D profiles. |

| Machining Progress | Contour accuracy: ±5 μm |

| Cutting Edge Quality | At 500× magnification: edge chipping < 1 μm; edge hone (passivation) < 3 μm |