Solution

Solution

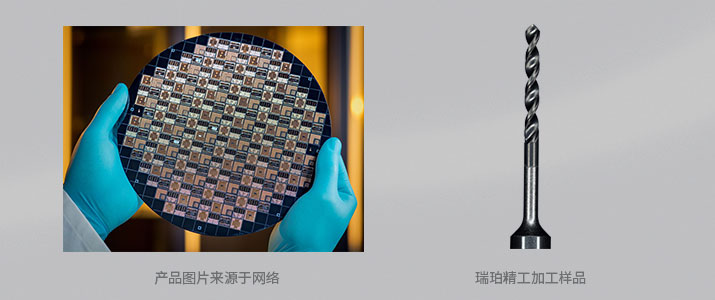

The five-axis laser tool processing machine can produce complex and highly precise micro PCD tools, meeting the machining requirements of semiconductor materials such as silicon carbide and alumina spray plates. These components have high initial costs and demand extremely stringent tool specifications.

In semiconductor chip packaging, micro-vias are essential for interconnecting circuits across different layers, particularly in multi-layer packaging or flip-chip designs. These micro-vias are typically fabricated using micro-drilling or laser drilling technologies to ensure precise electrical connections.

For optoelectronic devices in the semiconductor industry (e.g., laser diodes, LEDs, and fiber optic connectors), highly accurate micro-holes are critical for aligning optical components such as fibers. These holes require exceptional precision and are often manufactured using micro-drilling or laser drilling techniques to guarantee optimal optical alignment.

Self-developed ultrafast laser sources and algorithm software enable customized laser application scenarios and industrial machine tool solutions;

The equipment utilizes dual lasers for integrated roughing and finishing, ensuring high efficiency and superior quality;

Capable of complex micro-tool processing, excelling in engraving and micro-drilling of ultra-hard materials such as PCD;

Supports processes like edge etching and 3D metal texture machining, meeting diverse material processing needs in the semiconductor industry.