Solution

Solution

The Five-Axis Laser Processing Machine for Cutting Tools plays a vital role in the automotive industry thanks to its high precision and efficiency. With the superhard cutting tools produced on this platform, manufacturers can rapidly machine complex components—such as transmission housings, engine housings/blocks, turbine discs, and motor housings—greatly improving line flexibility and overall throughput.

Applying this five-axis laser processing solution not only raises manufacturing capability and productivity across the automotive sector, but also speeds the move toward higher precision, lightweighting, and greater customization of components.

The equipment uses proprietary laser sources and in-house algorithm software, enabling end-to-end solution design for customers and better responsiveness to evolving market demands—resulting in higher R&D efficiency and faster new-product turnaround;

Designed for stability and durability, the machine adopts a granite bed and other high-quality materials to ensure long-term accuracy and reliability—providing dependable tooling for automotive manufacturing and significantly improving tool life and machining efficiency;

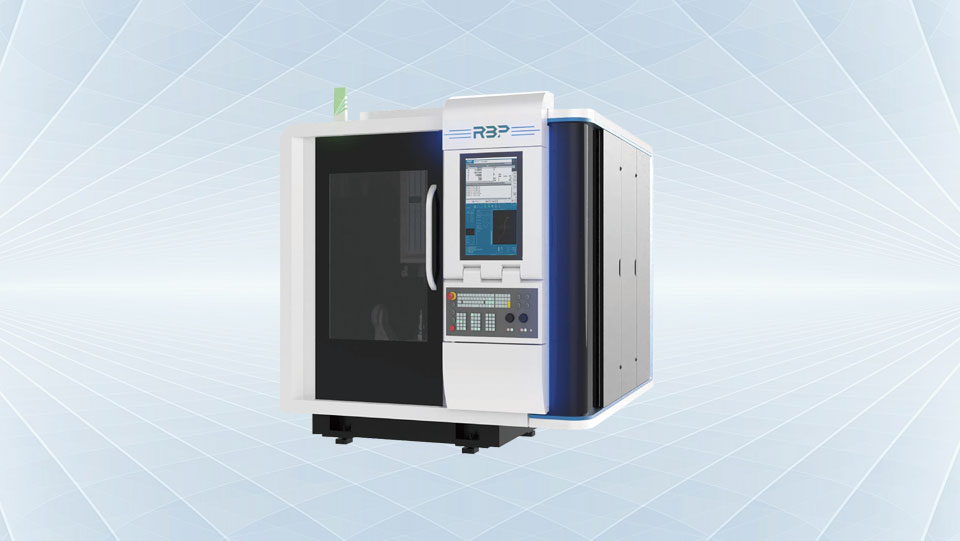

The LFS-M80 integrates turning, cutting, and engraving in one platform, simplifying customer processing workflows;

The LFS-M80 features power-loss protection, collision-avoidance, and toolpath monitoring, delivering comprehensive equipment safety;

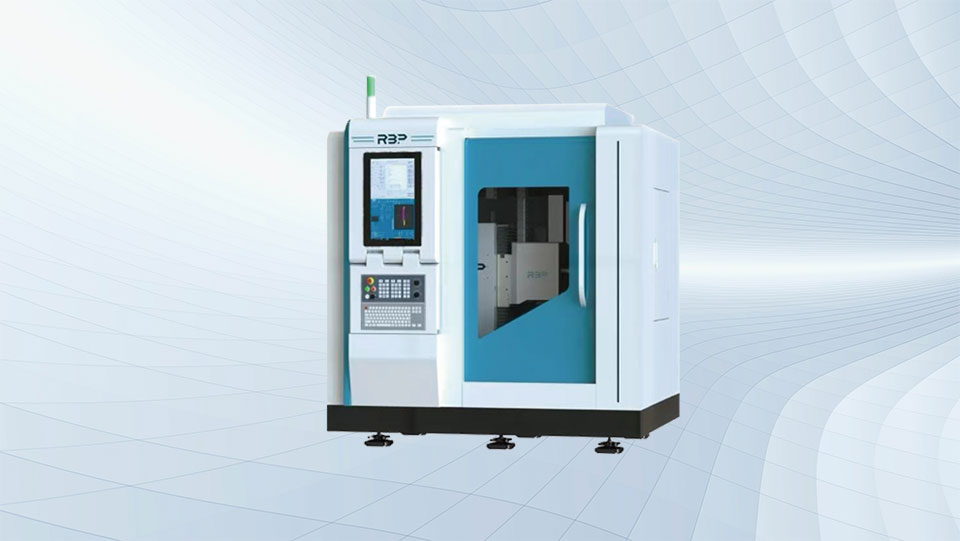

The LFS-P offers a 240 mm × 350 mm working envelope and supports roughing and finishing in one setup.